What is Bitumen?

Let’s begin with a brief overview of how crude oil is formed. The primary source of crude oil is the remains of microorganisms and marine algae that lived in aquatic environments millions of years ago. These remains settled at the bottoms of seas, swamps, or lakes and were buried under layers of mud, sand, and sediment. Over time, these sedimentary layers accumulated, placing the organic matter under intense pressure and heat. In the absence of oxygen, this matter gradually transformed into a waxy substance called kerogen. Over millions of years, kerogen, under increasing pressure and temperature, converted into crude oil and natural gas.

In some geological formations, the lighter components of crude oil (like gases and volatile compounds) either evaporate or get absorbed by rocks, leaving behind the heavier parts. This natural thickening process eventually turns the crude into bitumen (or asphalt), which is referred to as natural bitumen.

Natural bitumen can:

•Remain trapped in underground reservoirs (like Canada’s oil sands), or

•Reach the Earth’s surface through fractures or tectonic faults, forming natural bitumen lakes (like the “La Brea” Pitch Lake in Venezuela).

https://bitumenmag.com/News/comprehensive-overview-of-the-bitumen-market-in-2025

Refined Bitumen

Refined bitumen is a black, solid or highly viscous liquid material produced from the distillation of crude oil.

Main Components of Bitumen:

1.Organic compounds or hydrocarbons (about 90–95%) – including asphaltenes, resins, and maltenes

2.Inorganic compounds (about 5–10%) – such as sulfur, oxygen, nitrogen, and trace heavy metals

Typical Formula of Bitumen:

C₇₀H₁₁₀O₄S

Which means:

•70 carbon atoms (C)

•110 hydrogen atoms (H)

•4 oxygen atoms (O)

•1 sulfur atom (S)

Note: This formula represents an average composition of a typical bitumen sample. It varies depending on crude oil source, refining method, and production process.

Natural bitumen and oil sands generally contain higher amounts of sulfur and heavy metals (like nickel and vanadium). Bitumen consists of large molecules such as asphaltenes, resins, and maltenes, which do not have fixed chemical structures.

https://bitumenmag.com/News/investigating-the-mechanical-and-chemical-characteristics-of-bitumen-through-accelerated-chromatographic-fractionation

Uses of Bitumen

•Over 85% of global bitumen production is used in road construction

•10% is used for waterproofing

•3% goes to industrial uses (chemical industries, etc.)

•1% is used in artistic/special applications

•1% in other fields

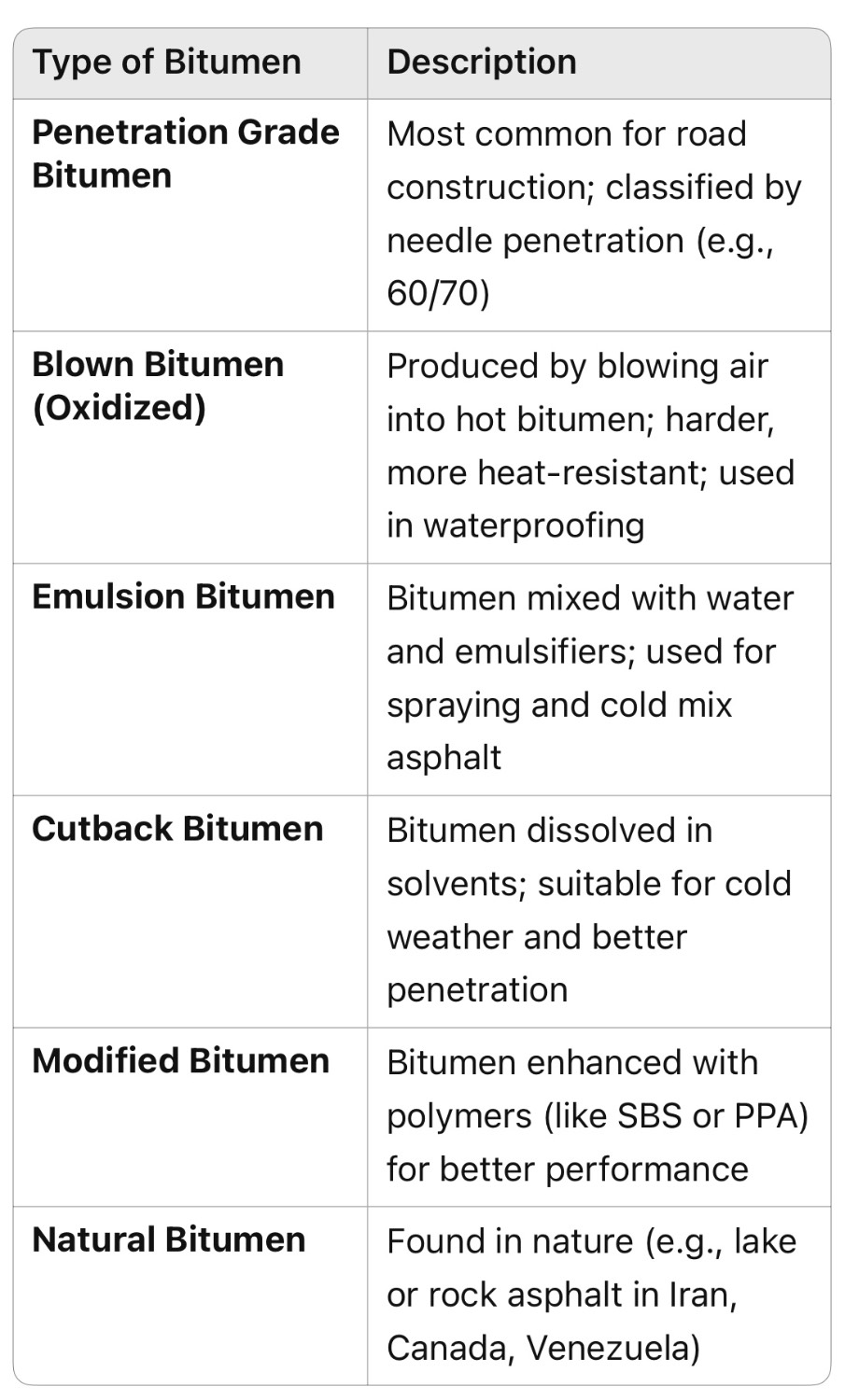

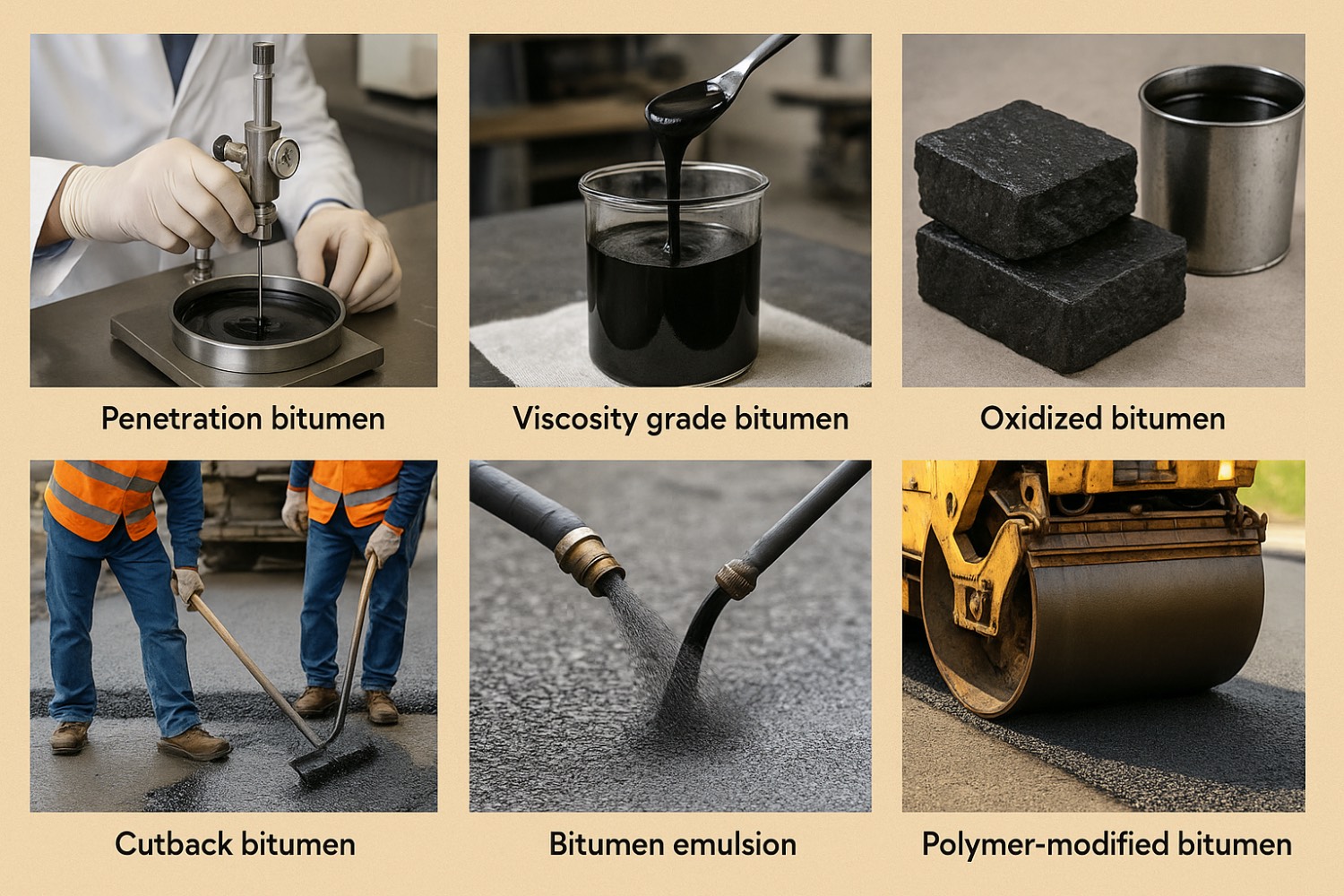

1. Natural Bitumen

Millions of years ago, microscopic organisms like algae were buried in aquatic environments. Under pressure and temperatures over 50°C, their remains turned into natural bitumen.

Natural bitumen is found in oil-rich hills and lakes in countries like Canada, Venezuela, Oman, and western Iran.

Types of Natural Bitumen:

1.Lake Bitumen: Found on the Earth’s surface in the form of natural asphalt lakes, like Trinidad’s La Brea Pitch Lake or Gachsaran’s Bitumen Lake in Iran.

2.Rock Asphalt: Bitumen that has penetrated into limestone or sandstone, extracted from solid deposits (e.g., in Ilam province of Iran or deposits in Iraq).

3.Gilsonite: A shiny, solid form of natural bitumen found in veins within rock formations – especially in western Iran (Ilam province) and parts of the U.S. (Utah).

Properties of Natural Bitumen:

•High resistance to water and weather

•Lower permeability and adhesion compared to petroleum bitumen

•Better thermal stability

•Longer lifespan in engineering applications

Applications of Natural Bitumen:

•Road construction and asphalt durability enhancement

•Ink and paint industries

•Waterproofing materials

•Additive to improve refined bitumen

•Drilling muds in oil extraction

2. Bitumen from Crude Oil Distillation

The main industrial source of bitumen is crude oil. During refining, crude oil is separated in distillation towers, and the remaining heavy residue called vacuum bottom is processed into bitumen.

Different types of bitumen—such as penetration grade and oxidized bitumen—are produced, mainly for road construction.

Production Process of Petroleum Bitumen

Refined bitumen is produced in two main distillation stages:

1.Atmospheric Distillation:

Crude oil is heated in a distillation tower. Light fractions (like gasoline, kerosene, and diesel) are separated. The remaining heavy residue is sent to the next stage.

2.Vacuum Distillation:

The heavy residue undergoes vacuum distillation at reduced pressure to separate heavier oils without thermal cracking. The final residue is called straight-run bitumen.

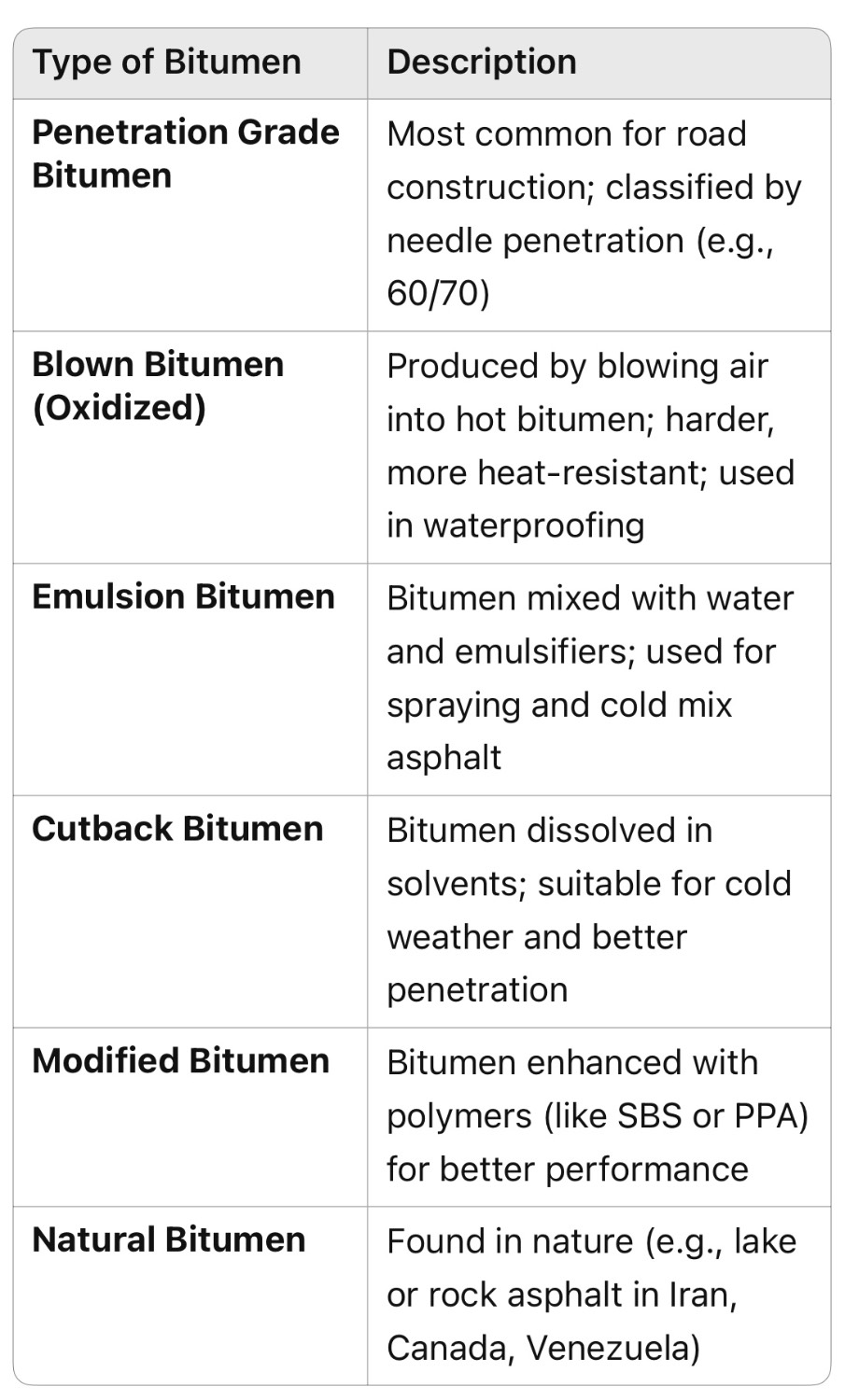

Types of Petroleum Bitumen and Their Uses

Grades:

•60/70: Most commonly used in road paving

•85/100: Suitable for cold regions

•40/50: Suitable for hot climates

Applications:

•Paving and road construction

•Waterproofing membranes (e.g., bituminous membrane/Isogam)

•Anti-corrosion coatings for pipelines

Bitumen is classified based on performance tests such as penetration, viscosity, consistency, and durability.

3. Blown Bitumen (Oxidized Bitumen)

•Production: Made by blowing air through petroleum bitumen at high temperatures.

•Properties:

•Harder than standard bitumen

•Greater heat resistance

•Uses:

•Waterproofing and building insulation

•Battery and electrode paste production

•Paper and cardboard industries

4. Bitumen Emulsion

•Definition: Bitumen dispersed in water with the help of emulsifying agents, presented as a liquid.

•Properties:

•Usable at ambient temperatures

•Ideal for cold applications

•Uses:

•Asphalt patching

•Thin asphalt layers (microsurfacing)

•Prime coat and tack coat applications

5. Cutback Bitumen

•Definition: Bitumen dissolved in petroleum solvents (e.g., gasoline, kerosene).

•Types:

•RC (Rapid-Curing)

•MC (Medium-Curing)

•SC (Slow-Curing)

•Uses:

•Cold-mix asphalt

•Bonding layers in road construction

•Cold regions where heating bitumen is difficult

6. Polymer-Modified Bitumen

•Definition: Bitumen modified with polymers like SBS or APP to improve performance.

•Properties:

•High resistance to cracking and temperature variations

•Excellent elasticity and flexibility

•Uses:

•Roads in regions with extreme weather

•Airport runways and highways

•Long-lasting waterproofing membranes

https://bitumenmag.com/News/reimagining-asphalt-how-recycled-plastics-are-shaping-the-future-of-road-construction

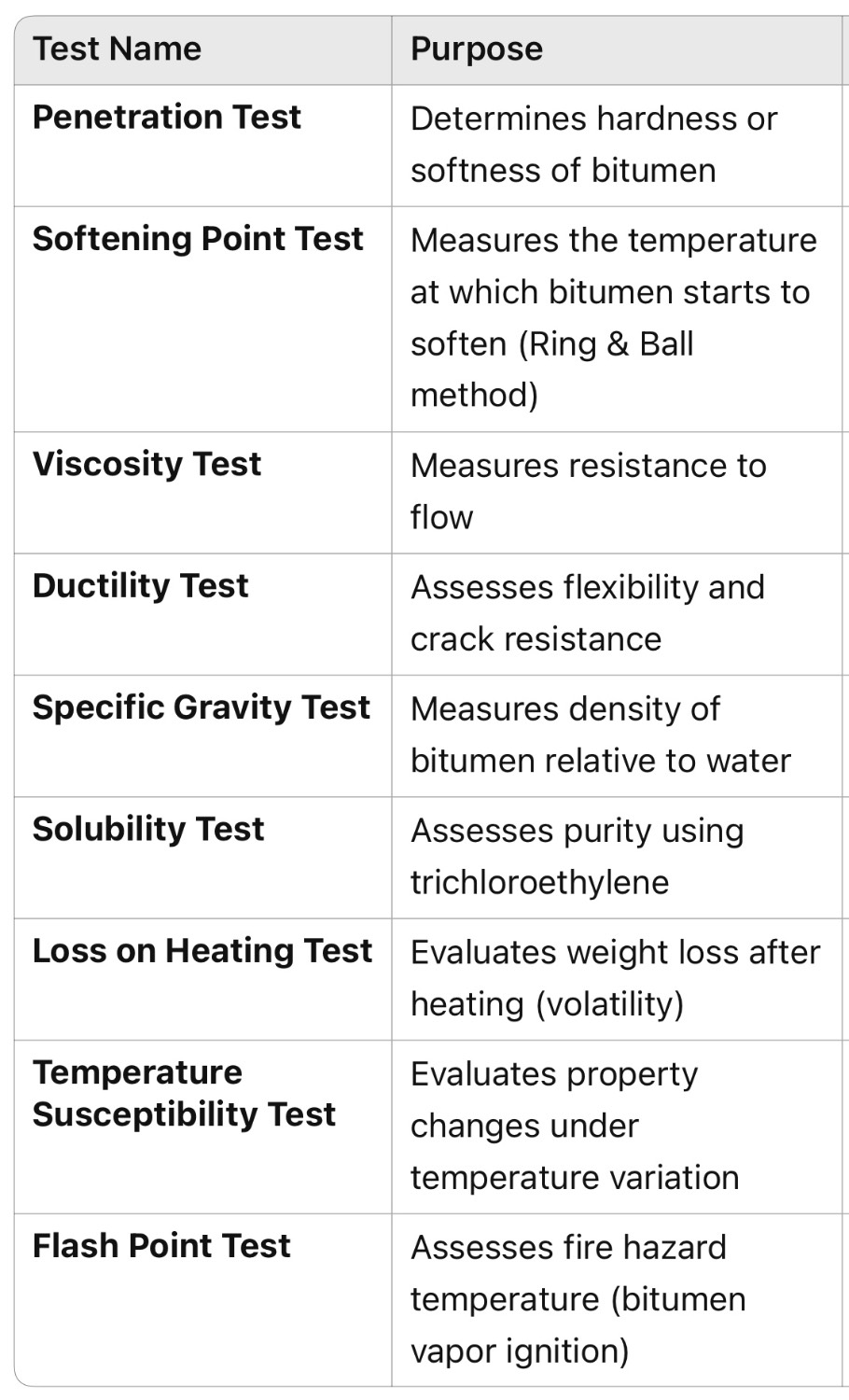

Bitumen Quality Tests

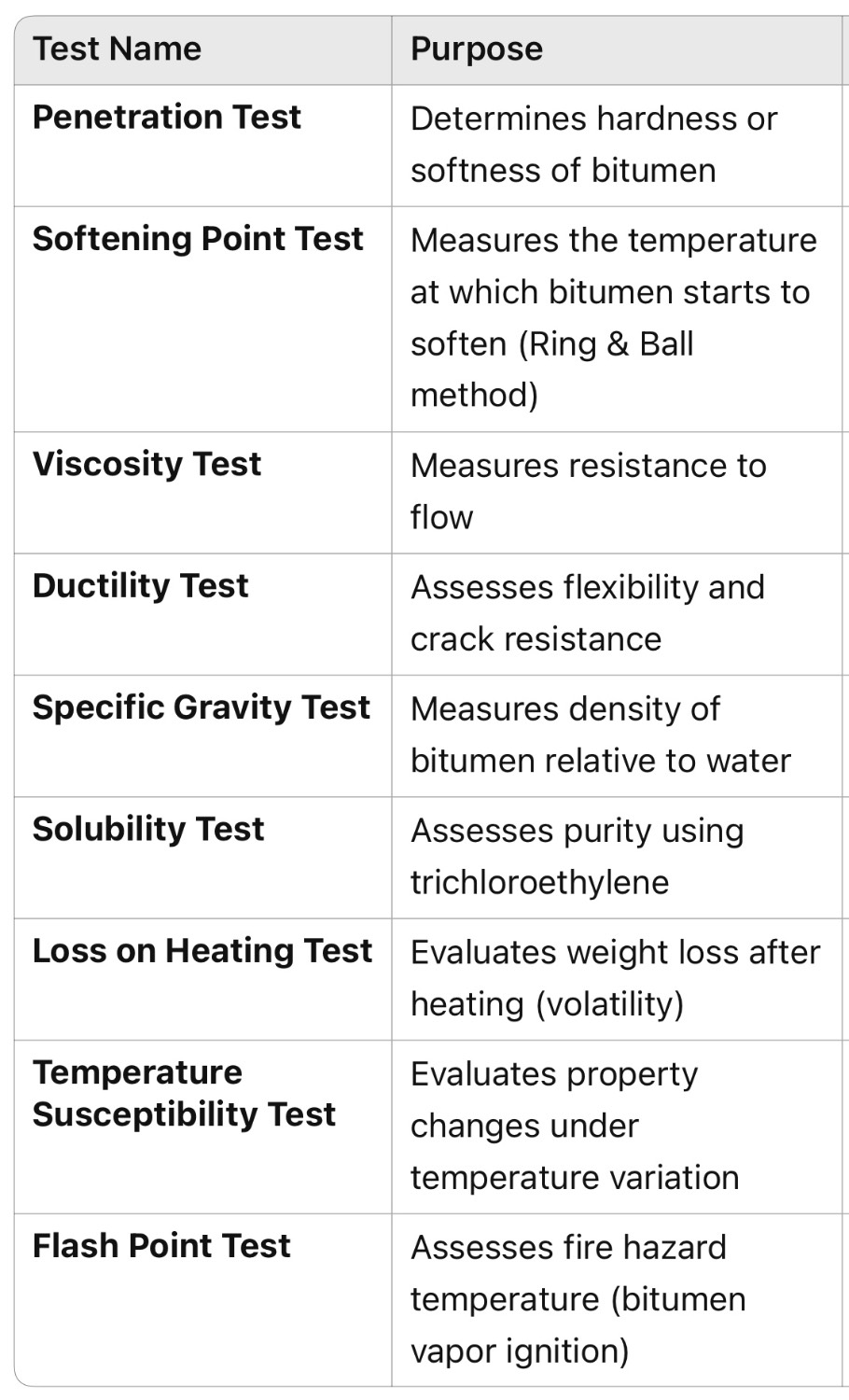

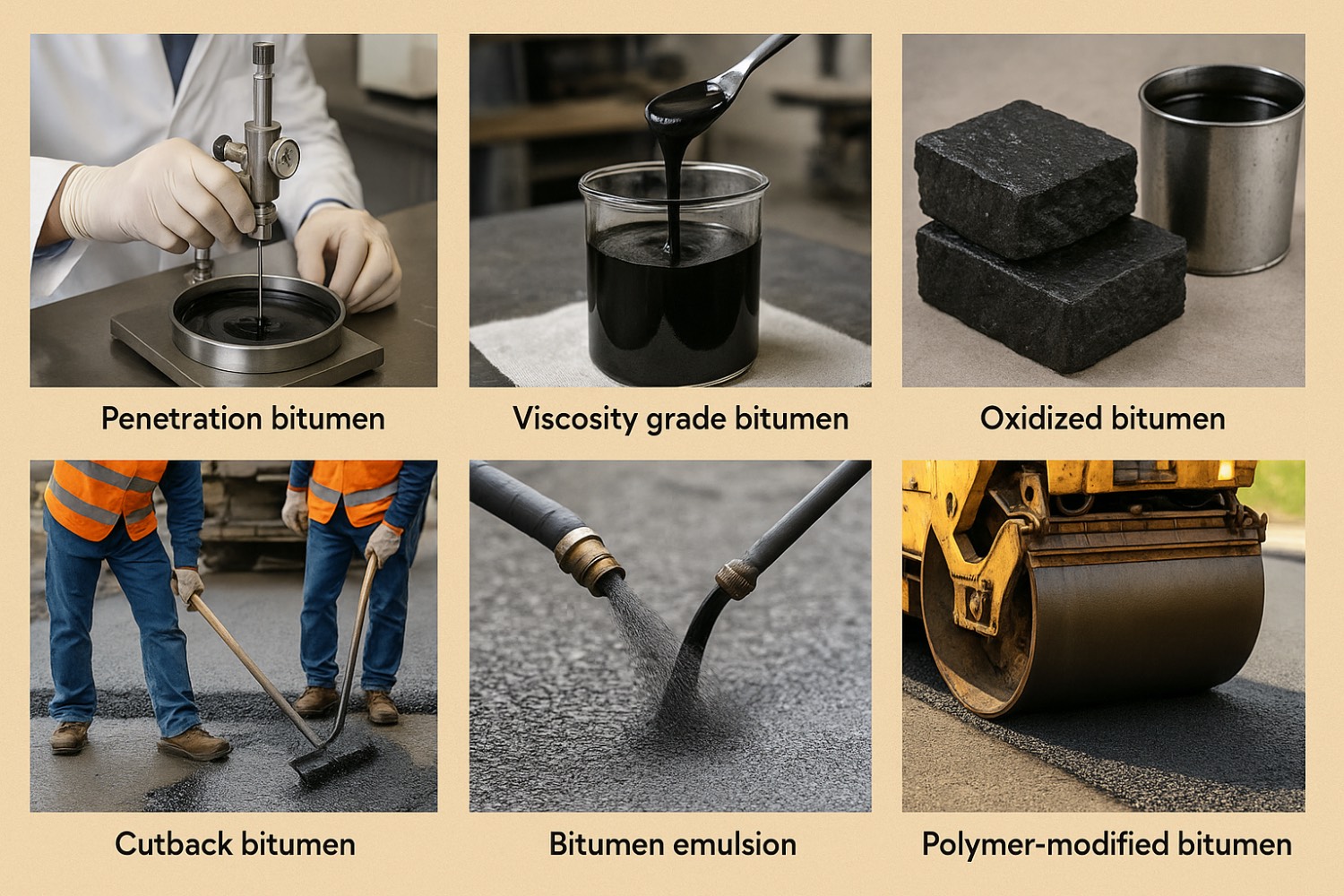

1. Penetration Test

•Purpose:

To determine the hardness or softness of bitumen.

•Method:

A standard needle with a 100 g load is allowed to penetrate vertically into the bitumen sample for 5 seconds at 25°C.

•Result:

The depth of penetration is measured in tenths of a millimeter. For example, bitumen grade 60/70 means the needle penetration is between 60 and 70 tenths of a millimeter.

2. Softening Point Test

(Using the Ring and Ball method)

•Purpose:

To determine the temperature at which bitumen begins to soften.

•Method:

A steel ball is placed on the bitumen contained in a brass ring. The assembly is heated in water or glycerin until the ball drops through the softened bitumen.

•Result:

The temperature at which the ball falls is recorded as the softening point.

3. Viscosity Test

•Purpose:

To measure the resistance of bitumen to flow.

•Method:

Conducted using a viscometer such as Saybolt Furol or Brookfield.

•Result:

Higher viscosity indicates greater resistance to flow.

4. Ductility Test

•Purpose:

To assess the flexibility and crack resistance of bitumen.

•Method:

A bitumen sample is stretched at a controlled speed in a ductility testing machine until it breaks.

•Result:

The elongation length before breaking is measured in centimeters. It should exceed 100 cm for standard bitumen.

5. Specific Gravity Test

•Purpose:

To determine the density of bitumen relative to water.

•Result: The specific gravity of bitumen is typically between 1.00 and 1.05.

6. Solubility Test (in Trichloroethylene)

•Purpose:

To assess the purity of bitumen.

•Method: Bitumen is dissolved in trichloroethylene, and the percentage of insoluble matter is measured.

•Result:

Standard bitumen should be at least 99% soluble in trichloroethylene.

7. Loss on Heating Test

•Purpose:

To determine the weight loss of bitumen when exposed to heat (indicating volatility of components).

•Result:

The weight loss should not exceed 1% of the original sample.

8. Temperature Susceptibility Test

•Purpose:

To evaluate how bitumen properties change with temperature variations.

9. Flash Point Test

•Purpose:

To assess the thermal safety of bitumen by identifying the temperature at which its vapors ignite.

•Result:

For road-grade bitumen, the flash point must be above 230°C.

https://bitumenmag.com/News/kazakhstan-targets-32-growth-in-road-bitumen-output-in-2025-aiming-for-over-1-million-tons

Global Bitumen Producers

Top Bitumen Producers:

1.United States

The largest bitumen producer in the world with an annual capacity of over 420 million tons. Major companies like Marathon Petroleum, Valero, and ExxonMobil account for most of the country’s output.

2.China

Ranks second globally, driven by large-scale infrastructure and urban development projects. China’s asphalt production capacity is projected to reach around 38 million tons by 2027.

3.Russia

Major production comes from oil giants such as Rosneft and Lukoil. With an annual production of approximately 30 million tons, Russia is among the world’s key bitumen producers.

4.Canada

Produces over 28 million tons of bitumen per year, ranking fourth globally. Most of the production comes from oil sands in Alberta, which are mined and refined into bitumen.

https://bitumenmag.com/News/malaysias-infrastructure-driven-bitumen-demand-surge-can-supply-keep-pace-with-national-development-goals

Top Bitumen Exporters (as of 2024):

•Canada – approx. 5.4 million tons, the world’s largest exporter

•Singapore – 2.6 million tons

•Iran – 2.6 million tons

•Iraq – 2.5 million tons

•United Arab Emirates – 2.3 million tons