What is bitumen emulsion?

Bitumen emulsion uses, bitumen emulsion structure, bitumen emulsion trade and market

Definition of Bitumen Emulsion

Bitumen emulsion can be defined as bitumen and water combined with the help of a chemical agent in such a way that they are not separated.

In fact, bitumen emulsion is a type of bitumen in which tiny bitumen particles are dispersed and suspended in water with the help of stabilizing chemicals (emulsifiers). By doing so, bitumen, which is sticky and solid by nature, is transformed into a low-viscosity homogeneous liquid. This renders bitumen emulsion suitable for application without high heat, and thus it is easy to apply under normal environmental conditions for the construction, maintenance, and repair activities of roads.

Composition of Bitumen Emulsion

Bitumen emulsion is a "bituminous yogurt drink."

To manufacture it, three components are needed:

1.Bitumen → the main sticky material we know from asphalt. 55–65% by total weight

2.Water → the medium in which bitumen is dispersed. 35–45% by total weight

3.Emulsifier (stabilizer) → up to 0.5% by total weight

• Bitumen and water naturally separate, so the emulsifier acts as an intermediary to suspend fine bitumen droplets in water and not deposited.

• The emulsifier also gives a positive or negative charge to bitumen particles, which subsequently determines where the emulsion works best (e.g., with granite or marble aggregates).

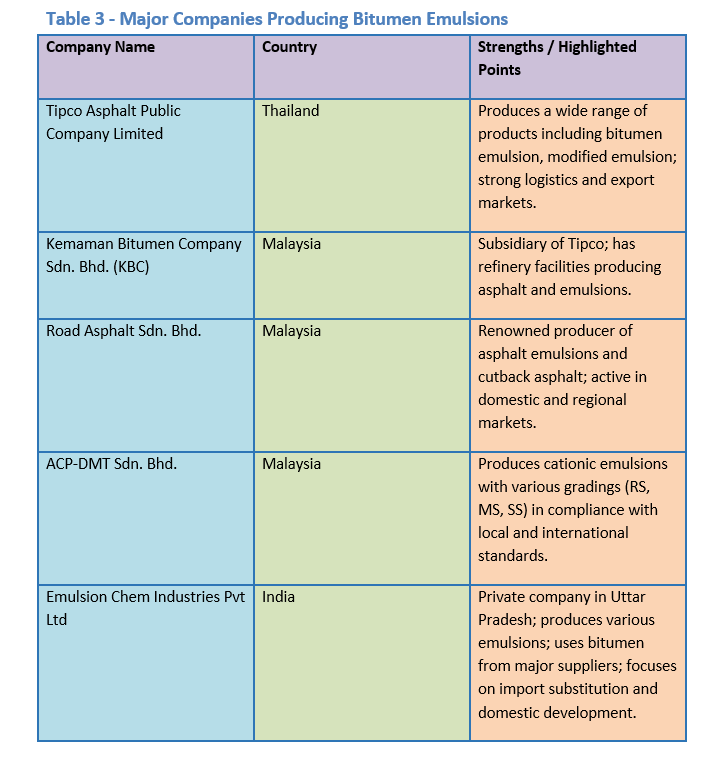

Types of Bitumen Emulsion

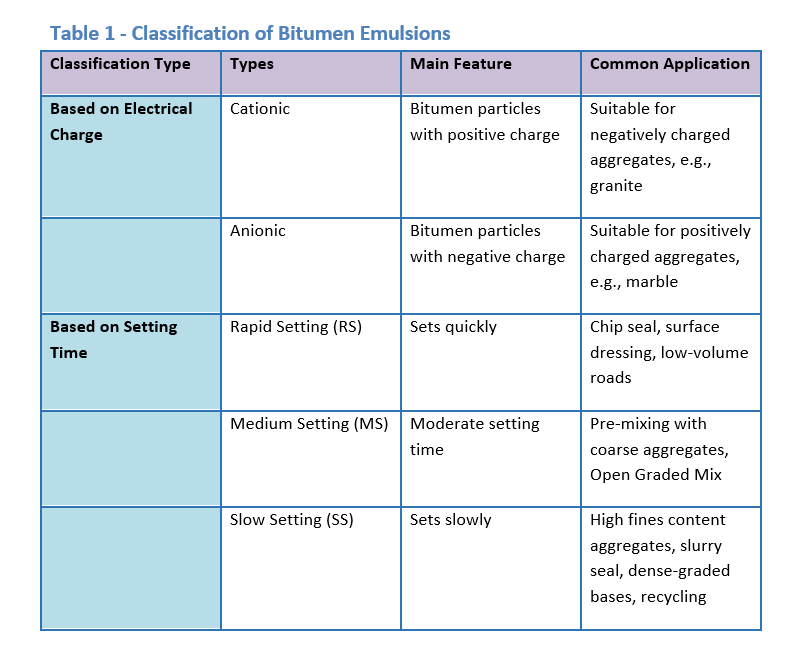

Bitumen emulsion can be classified based on two main properties:

1. Electrostatic Charge of Particles

• Cationic: Bitumen particles are positively charged and stick better to negatively charged aggregates.

• Anionic: Bitumen particles are negatively charged and stick better to positively charged aggregates.

2. Setting/Breaking Time

• Rapid Setting (RS): Quick reaction with aggregates and setting; for surface treatments and chip seals.

• Medium Setting (MS): Medium setting time; for initial mix with coarse aggregates or open-graded mixes.

• Slow Setting (SS): Sets slowly; utilized for aggregates with large surface areas, slurry seals, asphalt recycling, and dense bases.

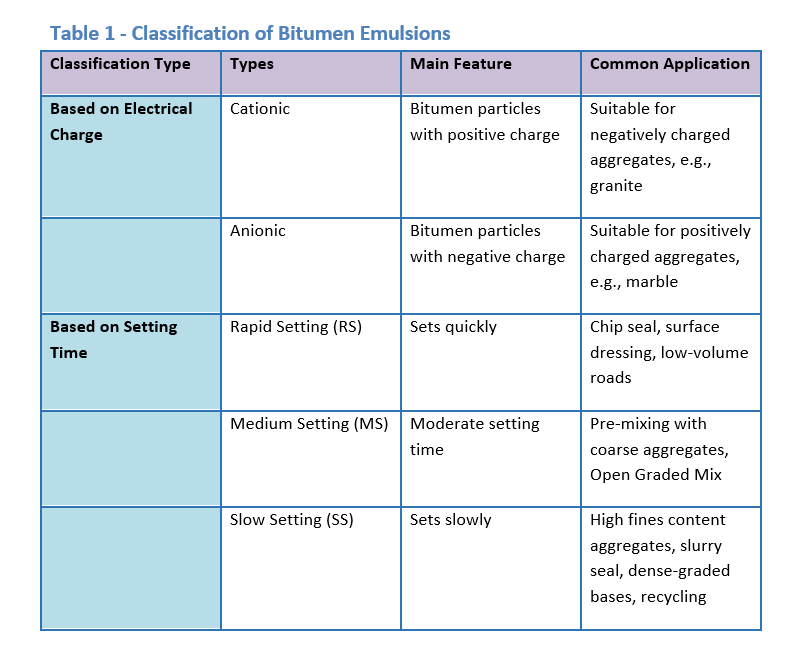

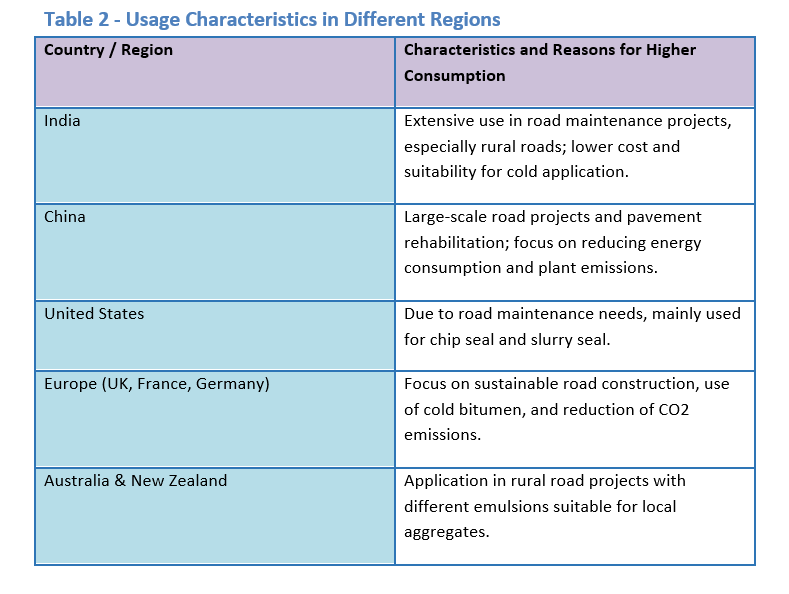

International application of bitumen emulsion is more prevalent in countries that:

1. Have a well-established road construction industry

2. Prioritize environmental and economic factors over the application of hot asphalt

Based on international statistics and road construction industry reports:

Leading Bitumen Emulsion Exporting Countries

1. India – 189 export shipments, the largest exporter of bitumen emulsion in the world, with a market share of about 31%.

2. Malaysia – 116 export shipments, market share of 19%.

3. South Africa – 92 export shipments, market share of 15%.

4. United Arab Emirates – 71 export shipments, market share of 11%.

5. Russia – 55 export shipments, market share of 8%.

6. Turkey – 33 export shipments, market share of 5%.

7. Germany – 27 shipments of export, with market share of 4%.

8. Thailand – 13 shipments of export, with market share of 2%.

9. Turkmenistan – 13 shipments of export, with market share of 2%.

10. Kazakhstan – 8 shipments of export, with market share of 1%.

Although Iran is one of the world's biggest bitumen producers, it ranks below the said countries in the manufacture of bitumen emulsions. Nonetheless, with its production capacity and geographic location, Iran has very good potential for the expansion of bitumen emulsion exports to Asian, African, and European countries.